Discover our comprehensive range of chemical and pharmaceutical processing capabilities

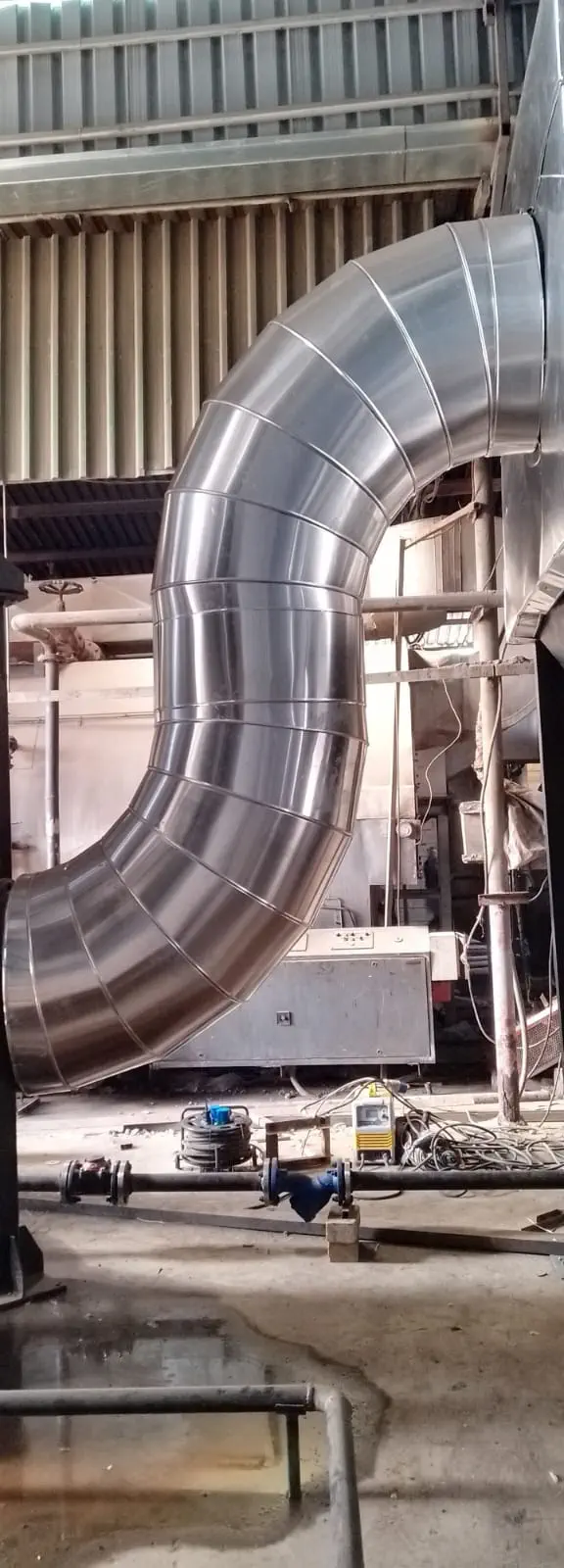

1. Process Steam Systems

We design and install clean steam systems specifically for pharmaceutical manufacturing, ensuring they meet stringent GMP standards, maintain absolute purity, prevent contamination, support critical sterilization processes, optimize thermal efficiency, provide reliable temperature control, and comply with all regulatory requirements for pharmaceutical-grade steam production and distribution in controlled environments.

2. Reactor Heating Solutions

We provide precise temperature control solutions for chemical reactors and process vessels, implementing advanced steam heating systems that ensure uniform heat distribution, accurate thermal management, safe pressure operation, optimized reaction kinetics, reliable performance, energy efficiency, and consistent product quality throughout diverse chemical processing and pharmaceutical manufacturing operations and production cycles.

3. Distillation Steam

We implement high-efficiency steam systems specifically designed for distillation and separation processes in chemical plants, ensuring precise temperature gradients, optimal vapor-liquid equilibrium, efficient heat transfer, consistent separation efficiency, reduced energy consumption, reliable operation, safety compliance, and enhanced product purity across various distillation applications and complex chemical processing operations requiring thermal separation.

4. Clean-in-Place Systems

We install steam-based Clean-in-Place (CIP) systems for pharmaceutical and chemical plant hygiene, designing automated cleaning solutions that ensure thorough sterilization, eliminate contamination risks, reduce manual cleaning requirements, maintain process integrity, comply with sanitation standards, optimize water and chemical usage, and support continuous production while meeting stringent regulatory and quality assurance requirements.

Precision Steam Solutions for Critical Processes

Ensure compliance and efficiency in your chemical or pharmaceutical operations.

Request Technical Consultation