Investigate our specialized range of sugar and tea processing capabilities

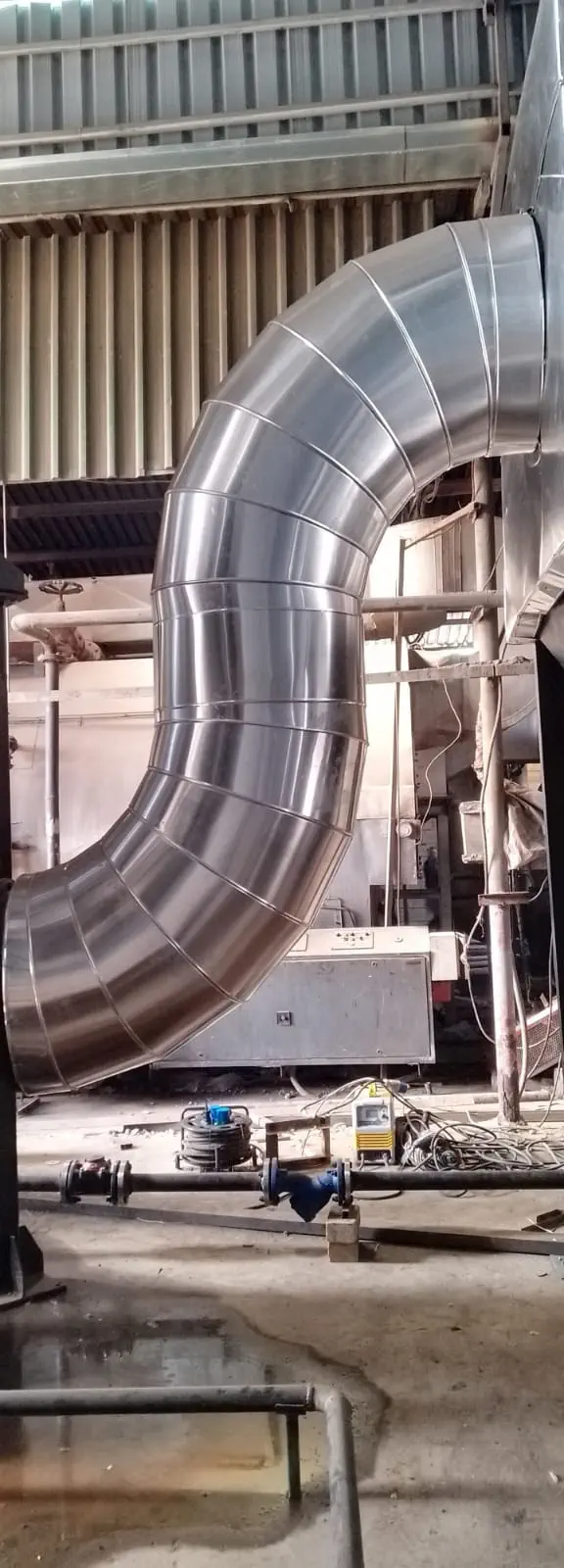

1. Tea Drying Systems

We design and install custom steam drying solutions specifically for KTDA tea factories, ensuring consistent quality, optimal moisture removal, efficient energy usage, uniform heat distribution, reliable operation, reduced fuel consumption, improved tea quality, and enhanced processing efficiency throughout tea production cycles and seasonal processing requirements.

2. Sugar Processing Steam

We implement high-pressure steam systems specifically designed for evaporation, crystallization, and refining processes in sugar mills, ensuring precise temperature control, optimal heat transfer, efficient energy utilization, consistent sugar quality, reduced processing time, reliable operation, and support for continuous sugar production during harvesting seasons and processing cycles.

3. Cogeneration Solutions

We design and install waste heat recovery and cogeneration systems for energy self-sufficiency in processing plants, implementing solutions that capture waste thermal energy, generate additional power, reduce energy costs, improve overall efficiency, support sustainable operations, provide reliable energy supply, and enhance the economic viability of sugar and tea processing facilities.

4. Seasonal Maintenance

We provide comprehensive pre-season boiler and steam system maintenance specifically for uninterrupted processing, conducting thorough inspections, performing necessary repairs, optimizing system performance, ensuring equipment readiness, reducing seasonal downtime, supporting reliable operation, and preparing processing plants for peak production periods and demanding processing cycles.

Maximize Your Processing Season Efficiency

Expert steam solutions for sugar mills and tea factories to optimize production and reduce downtime.

Discuss Plant Requirements