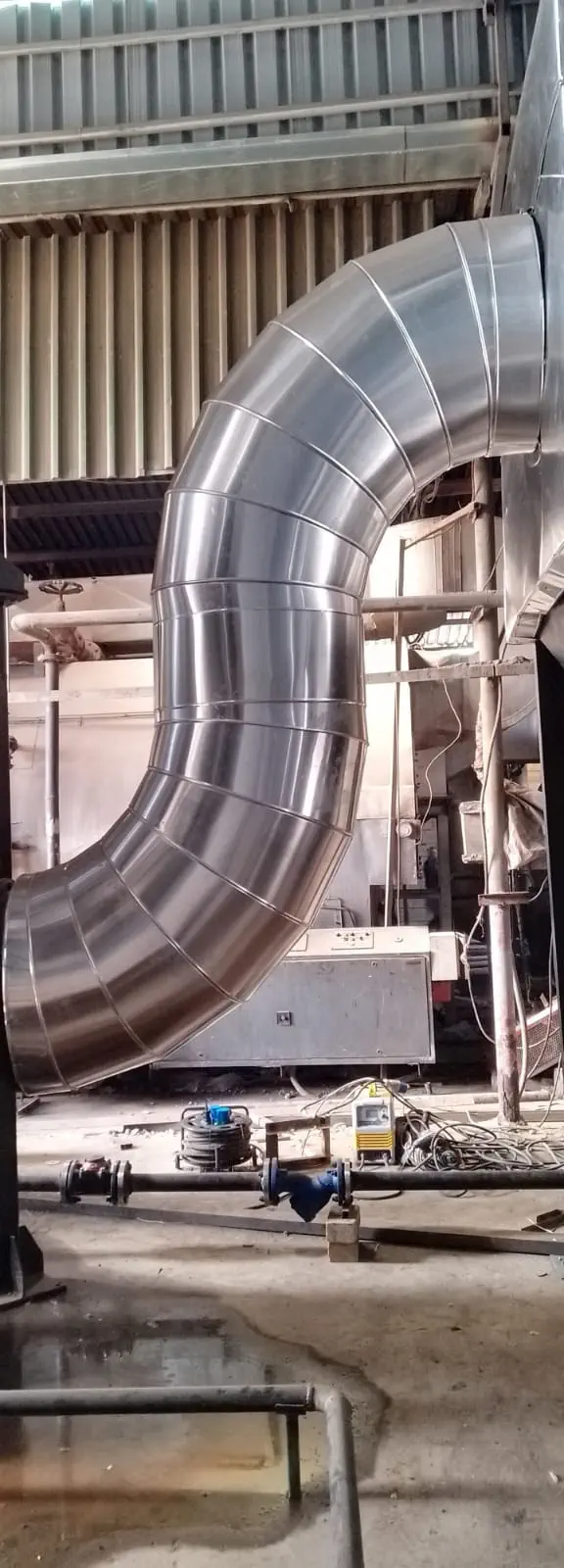

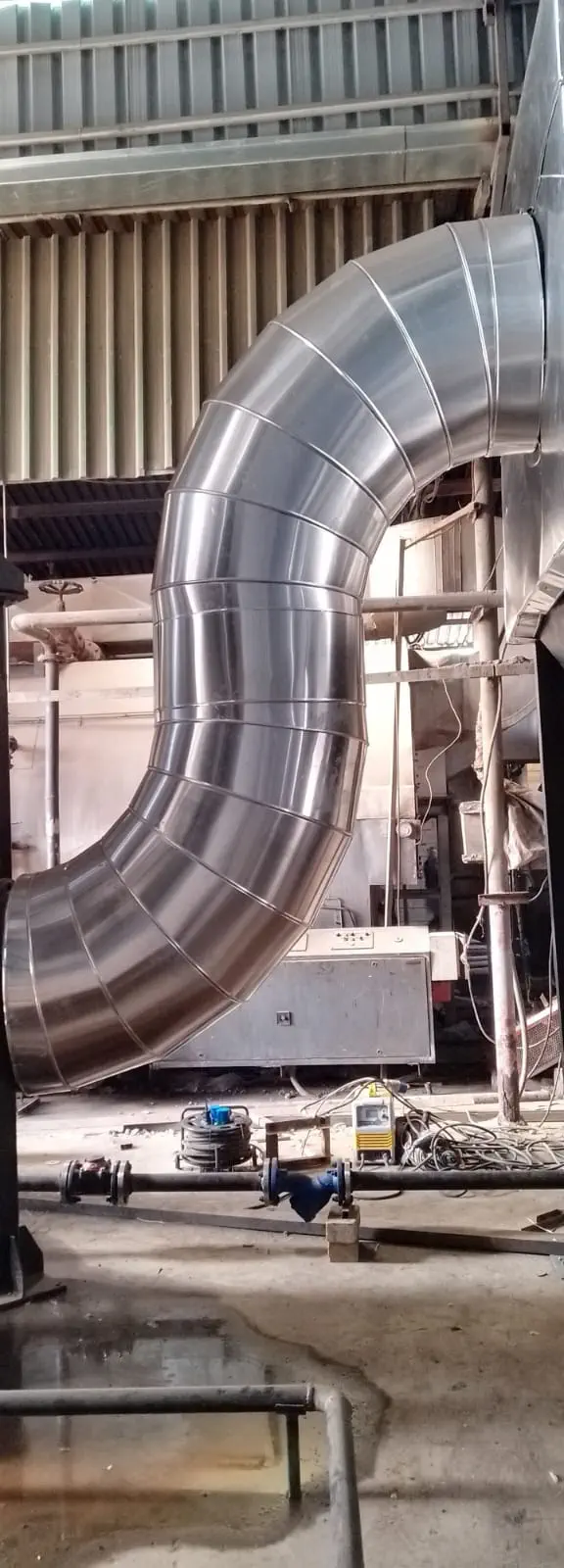

Fabrication & Installation

Ducts & Chimney Fabrication

Chemical Plant

8 Weeks

We delivered a full design, fabrication, and installation solution for industrial ducts and chimneys handling high-temperature and corrosive process gases. The project involved custom fabrication using appropriate materials, structural installation, and alignment to meet stringent safety, efficiency, and environmental regulations. Engineering considerations included airflow optimization, structural integrity, thermal expansion, and compliance with emissions standards. The final installation improved plant ventilation, ensured safe exhaust handling, and enhanced long-term system durability.

Custom Fabrication

Structural Installation

Compliance Design